Products & ServicesWhat is a press machine?

TOP > What is a press machine?

What we are

Company info

Products & Services

TOP > What is a press machine?

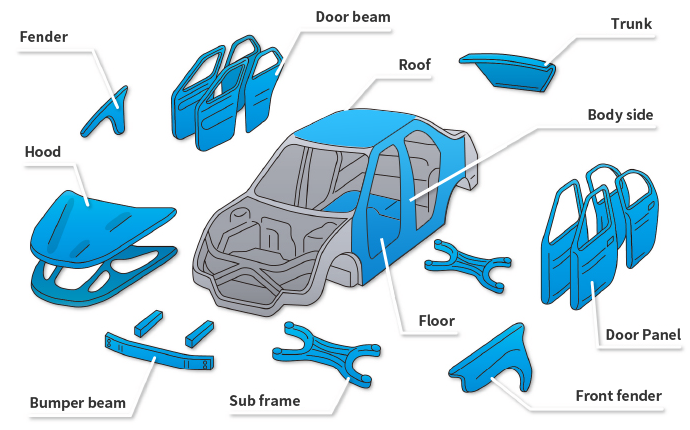

This machine applies strong pressure from the vertical direction to a thin metal material (steel plate, aluminum, etc.) and cuts and forms it into the shape of a die attached to the machine.

This machine can also bend, draw and punch the thin metal material depending on the shape of the die.

Press machinery is one of the indispensable machinery in the automotive industry and is working in automobile manufacturers and automobile parts manufacturers. We deliver them to the plant of domestic and overseas automobile-related companies.

Height:10m , Width:17m , Line length:22m ,

Weight:Approximately 850ton

| Press Capacity | Usage | |

|---|---|---|

| Small size | 1,000kN | Eyeglasses frames and home appliances |

| Medium size | 1,000kN~5,000kN |

| Large | 5,000~15,000kN | Outer panels for automobiles |

|---|---|---|

| Super large | 15,000kN以上 |

"kN"stands for kilonewton. 1kN is equal to 102 kilograms.